Understanding Forklift Maintenance Schedules

Maintaining a consistent forklift maintenance schedule is crucial for ensuring optimal performance, safety, and longevity. Regularly scheduled inspections and preventive maintenance can help identify and address potential issues before they escalate into costly repairs.

By adhering to manufacturer-recommended maintenance intervals, businesses can extend the lifespan of their forklift fleet, minimize downtime, and improve overall operational efficiency. This heading will provide insights into creating an effective forklift maintenance plan tailored to your specific needs.

Troubleshooting Common Forklift Electrical Issues

Electrical problems in forklifts can range from faulty wiring and malfunctioning sensors to battery issues and control system failures. Addressing these electrical challenges promptly is essential to avoid safety hazards and prevent further damage to the forklift.

This section will guide you through the process of identifying and resolving common forklift electrical issues, helping you maintain a reliable and well-functioning fleet. By understanding the root causes of these problems, you can implement proactive maintenance strategies to minimize disruptions and ensure uninterrupted productivity.

Optimizing Forklift Operator Training and Safety

Proper forklift operator training is crucial for maintaining a safe work environment and preventing costly accidents. Ensuring that your operators are well-versed in forklift operation, safety protocols, and maintenance best practices can significantly reduce the risk of injury and equipment damage.

This heading will provide insights into developing a comprehensive forklift operator training program, addressing topics such as pre-operation checks, load handling techniques, and emergency response procedures. By investing in thorough operator training, you can enhance overall forklift safety and operational efficiency.

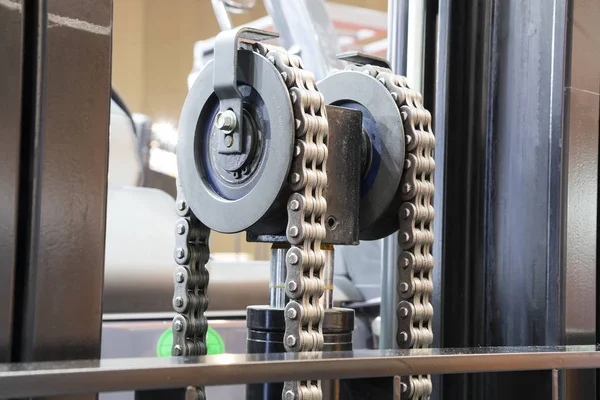

Strategies for Extending Forklift Lifespan

Maximizing the lifespan of your forklift fleet is essential for maintaining a cost-effective and sustainable operation. Implementing proactive maintenance strategies, utilizing high-quality parts, and adhering to recommended service intervals can significantly extend the usable life of your forklifts.

This section will explore various techniques and best practices for prolonging the lifespan of your forklift equipment, including proper storage and handling, regular inspections, and timely component replacements. By adopting these strategies, you can reduce the frequency of costly forklift replacements and ensure a longer return on your investment.