Forklifts typically come with various suspension systems designed to enhance stability and operator comfort. The main types of forklift suspensions include solid suspension systems, air suspension systems, and the three-point suspension system. Each type of suspension system offers unique benefits and is suited for different applications.

Understanding these systems helps in selecting the right forklift for specific tasks and ensuring smoother rides over various terrains. Whether you need a forklift for indoor or outdoor use, the right suspension system can significantly impact performance and safety.

Three-Point Suspension System

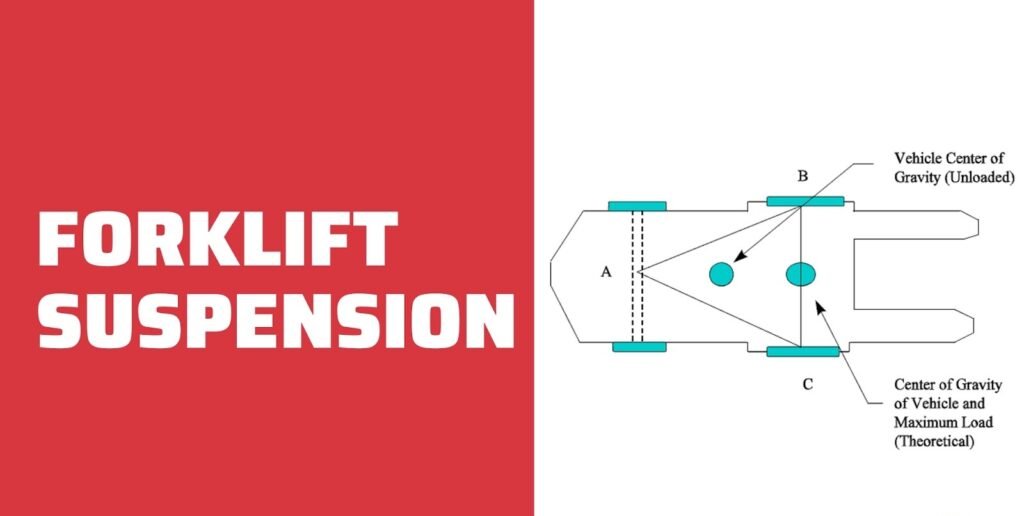

The three-point suspension system is a common feature in many forklifts, providing a balance between stability and flexibility. This system uses three points of support, typically involving the front axle and the rear wheels.

The stability triangle formed by this setup ensures load stability and reduces the risk of tipping, even when navigating uneven surfaces. The three-point suspension system is designed to maintain the forklift’s balance and improve overall handling, making it an essential aspect of forklift suspension.

Solid Suspension System

Solid suspension systems are known for their robustness and minimal maintenance requirements, making them ideal for heavy loads and rough surfaces. These systems provide excellent stability due to their rigid construction. However, the lack of flexibility can result in a rougher ride, especially on uneven terrain.

Solid suspension systems are commonly used in industrial settings where durability and load capacity are prioritized over ride comfort. Despite their rigidity, these systems play a crucial role in maintaining forklift suspension integrity under heavy-duty conditions.

Air Suspension for Forklifts

Air suspension systems offer superior comfort by utilizing air-filled bags to absorb shocks and vibrations. These systems adjust to the weight of the load, providing a smoother ride and reducing operator fatigue.

Forklift suspension seats equipped with air suspension can significantly enhance operator comfort, making long hours of operation more manageable. Air suspension is particularly beneficial in environments where ride quality and operator well-being are critical.

By maintaining optimal air pressure, these systems ensure consistent performance and comfort, making them a popular choice for modern forklifts.

Key Components of a Forklift’s Suspension System

A forklift’s suspension system comprises several critical components, each contributing to overall performance and safety. The rear wheels play a significant role in maintaining balance and maneuverability.

The stability triangle, formed by the front axle and rear wheels, ensures load stability by distributing weight evenly and preventing tipping. Shock absorbers are essential for reducing the impact of bumps and vibrations, enhancing operator comfort and load security.

Additionally, the leaf spring suspension helps in absorbing shocks and maintaining stability, especially when handling heavy loads. Regular maintenance of these components is crucial for ensuring the smooth operation and longevity of your forklift’s suspension system.

Types of Forklift Suspension Seats

Forklift Suspension seats are vital for operator comfort and safety, as they help to reduce the impact of vibrations and shocks during operation. Different types of suspension seats can be adjusted for weight and comfort, ensuring that operators can work efficiently without experiencing fatigue.

A well-designed forklift’s suspension system, including high-quality suspension seats, significantly enhances productivity and reduces the risk of injuries. Investing in the right suspension seats is essential for maintaining a safe and comfortable working environment.

Maintaining Forklift Suspension Systems

Proper care and maintenance of forklift suspension systems are vital to ensure their longevity and effectiveness. Regular inspections can identify issues such as loose connections, excessive wear, and improper air pressure in pneumatic systems. Using the appropriate safety equipment and performing routine checks can prevent costly repairs and ensure your forklift operates safely.

Suspension forklifts that are well-maintained provide better performance and reliability, reducing downtime and increasing operational efficiency. Adhering to a maintenance schedule is crucial for taking care of your forklift suspension.

Factors Affecting Forklift Suspension Performance

Several factors can influence the performance of a forklift’s suspension system, including load capacity, terrain, and maintenance. Handling heavy loads requires a robust suspension system to maintain stability and prevent damage. Uneven surfaces and rough terrain can challenge the suspension, necessitating more frequent maintenance.

Additionally, the exhaust system’s condition can impact overall performance, as a well-functioning exhaust system contributes to a smoother ride. Understanding these factors helps in optimizing your forklift’s suspension for better performance and longevity.

Ensuring Safety with Proper Forklift Suspension

Safety is paramount when operating forklifts, and a well-maintained suspension system plays a critical role in ensuring this. Regular pre-operation inspections are essential to check for any issues that could affect stability and performance, ensuring efficiency and safety.

Ensuring that safety lights are functioning, the parking brake is operational, and all other safety equipment is in good condition is crucial for preventing accidents. Proper forklift suspension contributes to overall safety by providing a stable and reliable platform for operations, protecting both the operator and the load.

Suspension Systems for Rough Terrain Forklifts

Forklifts operating on rough terrain require robust suspension systems to handle uneven surfaces and provide stability. Outdoor forklifts are often equipped with pneumatic tires and advanced suspension systems that absorb shocks and vibrations, ensuring a smoother ride. These features are crucial for maintaining load stability and operator comfort in challenging environments.

A well-designed suspension system can significantly enhance the performance and safety of forklifts used in rough terrain, reducing wear and tear on the equipment and improving productivity.

Mechanical Suspension Systems in Forklifts

Mechanical suspension systems are common in many forklifts, providing a balance between durability and performance. These systems use springs and shock absorbers to absorb bumps and maintain stability. Regular maintenance is crucial for taking care of forklift suspension systems, ensuring they perform optimally over time.

Monitoring the battery or fuel level is also important, as it affects the overall balance and performance of the forklift. Mechanical suspensions are reliable, but regular inspections can help identify wear and tear, preventing potential issues.

Pre-Operation Inspection and Safety Features

Performing a thorough pre-operation inspection is vital for ensuring the safety and efficiency of your forklift. This includes checking the seat belt, overhead guard, and ensuring the forklift’s center of gravity is balanced. Most forklifts are equipped with safety features like an overhead guard to protect the operator from falling objects.

Ensuring that these features are in good working condition can prevent accidents and enhance operator safety. Additionally, inspecting the pivot pin and other critical components can help maintain stability, especially when handling heavy loads or navigating uneven terrain.

Importance of Full Suspension Systems in Load Handling

Full suspension systems are designed to provide maximum comfort and stability for operators, especially when handling heavy loads. These systems help in maintaining the combined center of gravity, ensuring that the forklift remains stable during operation.

When moving the forklift forward or navigating rough terrain, the suspension system plays a crucial role in absorbing shocks and preventing gravity shifts that could lead to instability. By ensuring your forklift is equipped with a robust suspension system, you can improve load handling and overall safety in your operations.

Why Choose Upright Forklift Repair?

At Upright Forklift Repair, we specialize in ensuring optimal performance and operator comfort throughexpert maintenance and repair services. Our team is dedicated to enhancing shock absorption and overall functionality of your forklifts. Trust us for reliable service and support to keep your forklifts running smoothly.