Optimizing Forklift Maintenance Schedules

Proper maintenance scheduling is crucial for ensuring the longevity and efficiency of forklift operations. By adhering to a well-planned maintenance regimen, businesses can minimize downtime, reduce repair costs, and enhance the overall performance of their material handling equipment.

Regular inspections, lubrication, and preventive maintenance tasks can help identify potential issues before they escalate, allowing for timely interventions and proactive problem-solving. This approach not only extends the lifespan of forklifts but also promotes workplace safety and operational continuity.

Forklift Operator Training and Safety Protocols

Ensuring the safety of forklift operators is a top priority for any business. Comprehensive training programs that cover operating procedures, load handling, and emergency response protocols can help mitigate the risk of accidents and injuries on the job.

By empowering operators with the knowledge and skills to handle forklifts responsibly, companies can foster a culture of safety, improve productivity, and protect their valuable assets. Regular refresher courses and ongoing monitoring of operator performance are also essential for maintaining high safety standards.

Forklift Rental Strategies for Temporary or Fluctuating Needs

Businesses with variable or seasonal material handling requirements may find forklift rental a more cost-effective solution than maintaining a permanent fleet. Rental options provide the flexibility to scale up or down as needed, ensuring that operations can adapt to changing demands without the burden of ownership.

By leveraging rental services, companies can access the latest forklift models, eliminate maintenance responsibilities, and only pay for the equipment they use. This approach can help optimize capital expenditures, improve cash flow, and enable businesses to focus on their core operations.

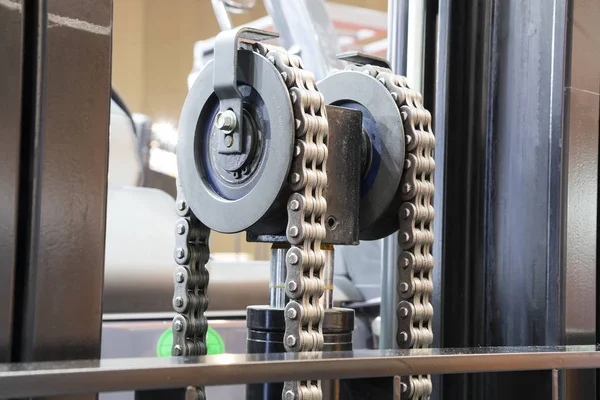

Forklift Parts Sourcing and Inventory Management

Maintaining a well-stocked inventory of forklift parts is crucial for minimizing downtime and ensuring the continuous operation of material handling equipment. By partnering with reliable suppliers and optimizing parts sourcing strategies, businesses can secure the components they need to keep their forklifts running at peak performance.

Effective inventory management practices, such as forecasting demand, negotiating bulk discounts, and implementing just-in-time delivery, can help businesses maintain a balanced parts supply and avoid costly delays or unexpected repair expenses.