Benefits of Regular Forklift Maintenance

Consistent forklift maintenance is crucial for ensuring the longevity and optimal performance of your equipment. By adhering to a regular maintenance schedule, businesses can minimize downtime, reduce operating costs, and enhance the safety of their forklift operations.

Proper maintenance helps identify potential issues early on, allowing for timely repairs and preventing more significant problems down the line. This proactive approach not only extends the lifespan of your forklifts but also improves energy efficiency and reduces the risk of accidents, keeping your workplace safe and productive.

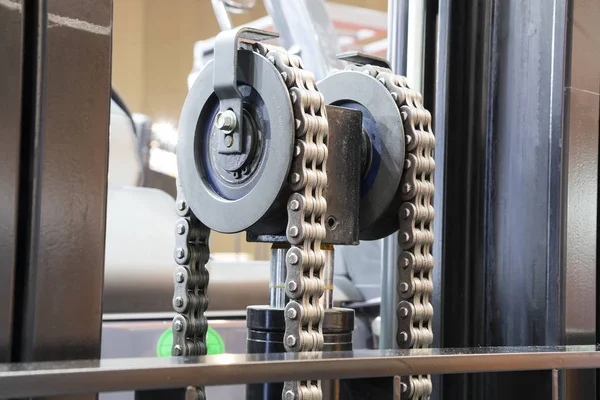

Choosing the Right Forklift Parts and Accessories

Selecting the appropriate forklift parts and accessories is essential for maintaining the functionality and performance of your equipment. From replacement tires and batteries to attachments and safety features, each component plays a vital role in the overall efficiency and reliability of your forklifts.

By carefully matching parts and accessories to your specific forklift models and operating needs, you can ensure optimal productivity, reduce the frequency of breakdowns, and keep your operations running smoothly. Consulting with experienced forklift technicians can help you make informed decisions and identify the most suitable solutions for your business.

Forklift Operator Training and Safety Protocols

Ensuring the safety of forklift operators is a critical aspect of maintaining a productive and efficient workplace. Comprehensive operator training programs cover topics such as equipment handling, load management, and accident prevention, equipping your employees with the knowledge and skills necessary to operate forklifts safely.

Implementing robust safety protocols, including regular inspections, clear operating procedures, and ongoing training, can help reduce the risk of accidents, minimize downtime, and protect your workforce. By prioritizing forklift operator safety, you can create a safer work environment and maintain the reliability of your equipment for the long term.

Maximizing Forklift Uptime through Strategic Maintenance

Maximizing forklift uptime is essential for maintaining a productive and efficient workplace. By implementing a strategic maintenance plan, businesses can reduce the frequency and duration of equipment downtime, ensuring that their forklifts are available when they are needed most.

This approach involves proactive maintenance, prompt repairs, and effective inventory management of critical parts and components. By anticipating potential issues and addressing them before they lead to breakdowns, businesses can minimize disruptions, maintain operational continuity, and optimize the overall performance of their forklift fleet.