Forklift Safety Maintenance and Inspections

Ensuring the safety of forklift operations is crucial for maintaining a productive and secure work environment. This section covers essential forklift safety maintenance procedures, such as regular inspections, to identify and address potential issues before they lead to accidents or downtime.

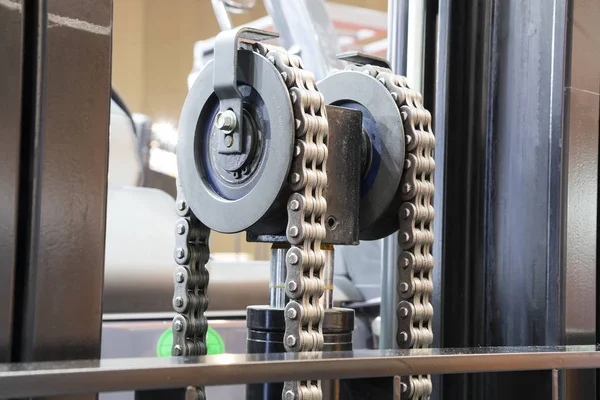

Regular forklift inspections should include checking for proper functioning of critical components like brakes, steering, and load-handling mechanisms. Identifying and addressing safety concerns promptly can help prevent costly repairs and protect your workforce.

Troubleshooting Common Forklift Malfunctions

Proactively addressing forklift malfunctions can help minimize downtime and maintain operational efficiency. This section provides guidance on diagnosing and resolving common issues, such as engine problems, hydraulic system failures, and electrical system faults.

By understanding the root causes of forklift malfunctions and implementing appropriate repair strategies, businesses can ensure their forklifts remain reliable and productive, ultimately enhancing their overall operations.

Forklift Preventive Maintenance Strategies

Implementing effective preventive maintenance strategies is key to maximizing the lifespan and performance of your forklift fleet. This section explores best practices for developing a comprehensive maintenance plan, including scheduled inspections, lubrication, and component replacements.

By proactively maintaining their forklifts, businesses can reduce the risk of unexpected breakdowns, minimize repair costs, and ensure their equipment remains in optimal condition to support their operations.

Forklift Operator Training and Certification

Proper forklift operator training and certification are essential for maintaining a safe and efficient work environment. This section covers the importance of providing comprehensive training programs, covering topics such as operating procedures, load management, and safety protocols.

Investing in forklift operator training not only helps protect your workforce but also ensures your equipment is used effectively, maximizing productivity and minimizing the risk of accidents or damage.

Forklift Safety Maintenance and Inspections

Ensuring the safety of forklift operations is crucial for maintaining a productive and secure work environment. This section covers essential forklift safety maintenance procedures, such as regular inspections, to identify and address potential issues before they lead to accidents or downtime.

Regular forklift inspections should include checking for proper functioning of critical components like brakes, steering, and load-handling mechanisms. Identifying and addressing safety concerns promptly can help prevent costly repairs and protect your workforce.

Troubleshooting Common Forklift Malfunctions

Proactively addressing forklift malfunctions can help minimize downtime and maintain operational efficiency. This section provides guidance on diagnosing and resolving common issues, such as engine problems, hydraulic system failures, and electrical system faults.

By understanding the root causes of forklift malfunctions and implementing appropriate repair strategies, businesses can ensure their forklifts remain reliable and productive, ultimately enhancing their overall operations.

Forklift Preventive Maintenance Strategies

Implementing effective preventive maintenance strategies is key to maximizing the lifespan and performance of your forklift fleet. This section explores best practices for developing a comprehensive maintenance plan, including scheduled inspections, lubrication, and component replacements.

By proactively maintaining their forklifts, businesses can reduce the risk of unexpected breakdowns, minimize repair costs, and ensure their equipment remains in optimal condition to support their operations.

Forklift Operator Training and Certification

Proper forklift operator training and certification are essential for maintaining a safe and efficient work environment. This section covers the importance of providing comprehensive training programs, covering topics such as operating procedures, load management, and safety protocols.

Investing in forklift operator training not only helps protect your workforce but also ensures your equipment is used effectively, maximizing productivity and minimizing the risk of accidents or damage.