Forklift technology is rapidly evolving, introducing innovative solutions that significantly enhance efficiency, safety, and sustainability in the material handling industry. For businesses in Houston and Humble, TX, staying up-to-date with these emerging technologies is essential for maintaining a competitive edge and ensuring optimal forklift operations.

Modern advancements, such as electric forklifts and automated forklifts, offer a range of benefits—from reducing the carbon footprint to minimizing repair costs and improving overall operational efficiency. As the industry continues to innovate, integrating these cutting-edge technologies is becoming a fundamental aspect of forklift design and repair. This blog will explore how businesses can leverage these technological advancements to enhance productivity, ensure a safer working environment, and reduce operational costs.

Forklift Technology Advancements: Revolutionizing Material Handling

The material handling industry is undergoing a significant transformation, driven by the latest trends in forklift technology. Innovations such as electric forklifts, automated guided vehicles (AGVs), and AI-powered machines are at the forefront of this revolution, enabling more efficient and safer forklift operations.

Electric forklifts, for example, are becoming increasingly popular due to their lower operational costs and environmentally friendly alternative to traditional gas-powered models. These forklifts are particularly advantageous in reducing emissions and enhancing operational efficiency, making them ideal for businesses aiming to decrease their carbon footprint.

On the other hand, automated forklifts are equipped with advanced features like smart sensors and collision avoidance systems. These technologies not only enhance workplace safety by preventing accidents but also increase productivity by allowing forklifts to operate with minimal manual intervention. By embracing these emerging technologies, businesses in Houston and Humble can optimize their forklift operations, reduce downtime, and achieve greater efficiency in their material handling processes.

Electric Forklifts: A Sustainable and Cost-Effective Choice

As the demand for sustainable practices grows, electric forklifts are emerging as a leading solution in the forklift industry. Unlike traditional gas-powered models, electric forklifts provide numerous advantages that make them a preferred choice for businesses looking to enhance both operational efficiency and sustainability.

One of the primary benefits of electric forklifts is their ability to significantly reduce the carbon footprint. These forklifts run on electric power rather than fossil fuels, which not only minimizes greenhouse gas emissions but also aligns with the increasing demand for environmentally friendly alternatives in industrial operations.

Beyond sustainability, electric forklifts offer substantial cost savings. They have lower operational costs due to reduced fuel consumption and fewer maintenance requirements. With fewer moving parts than their gas-powered counterparts, electric forklifts typically experience less wear and tear, leading to lower repair costs and longer lifespans.

Additionally, electric forklifts are quieter than traditional forklifts, which can contribute to a safer and more comfortable working environment, especially in indoor settings. By investing in electric forklifts, businesses can achieve greater efficiency and reduce both their environmental impact and operational costs.

Automated Forklifts and Robotics Integration: Increasing Efficiency and Safety

The integration of automated forklifts and automated guided vehicles (AGVs) is transforming the forklift industry, providing significant improvements in both efficiency and safety. Automated forklifts, equipped with advanced technologies such as artificial intelligence (AI) and machine learning, are capable of operating with minimal manual intervention.

These forklifts can perform repetitive tasks continuously, without breaks, which significantly boosts productivity and reduces the need for a large workforce. As a result, businesses can achieve considerable savings on labor costs while maintaining a high level of operational efficiency.

In addition to improving efficiency, automated forklifts and AGVs contribute to a safer working environment. They are designed to navigate tight spaces and complex warehouse layouts, thanks to their ability to optimize routes and avoid obstacles. The integration of advanced robotics allows these machines to work alongside human operators, further enhancing productivity while reducing the risk of accidents.

For businesses in Houston and Humble, TX, embracing automated forklifts means not only improving forklift operations but also enhancing safety standards in their facilities. By utilizing these cutting-edge technologies, companies can minimize workplace injuries, reduce downtime due to accidents, and ensure a safer, more efficient workplace.

Enhancing Safety with Smart Sensors and Collision Avoidance Systems

Safety is a paramount concern in forklift operations, and emerging technologies such as smart sensors and collision avoidance systems are playing a crucial role in enhancing workplace safety. Smart sensors are designed to detect obstacles in real-time, alerting operators to potential hazards and allowing them to take corrective actions promptly.

This technology is particularly beneficial in preventing accidents in busy warehouse environments where visibility might be limited. By providing real-time feedback, smart sensors help reduce the risk of collisions, thereby safeguarding both operators and inventory.

Collision avoidance systems take safety a step further by autonomously slowing down or stopping the forklift when an obstacle is detected. This automatic response helps prevent accidents, especially in scenarios where operator reaction time might be insufficient. For businesses in Houston and Humble, TX, integrating these safety technologies into their forklift fleet can significantly reduce the likelihood of workplace injuries and create a safer working environment.

By investing in advanced safety features, companies not only protect their workforce but also reduce the potential costs associated with accidents and equipment damage, ensuring a more efficient and secure operation.

The Role of Predictive Maintenance in Forklift Operations

Predictive maintenance is becoming a critical component in modern forklift operations. By leveraging real-time data and advanced analytics, predictive maintenance allows businesses to monitor the health of their forklifts and predict potential failures before they occur. This proactive approach is vital for reducing downtime and minimizing unexpected repair costs, which can be particularly disruptive in high-demand environments like warehouses and industrial sites.

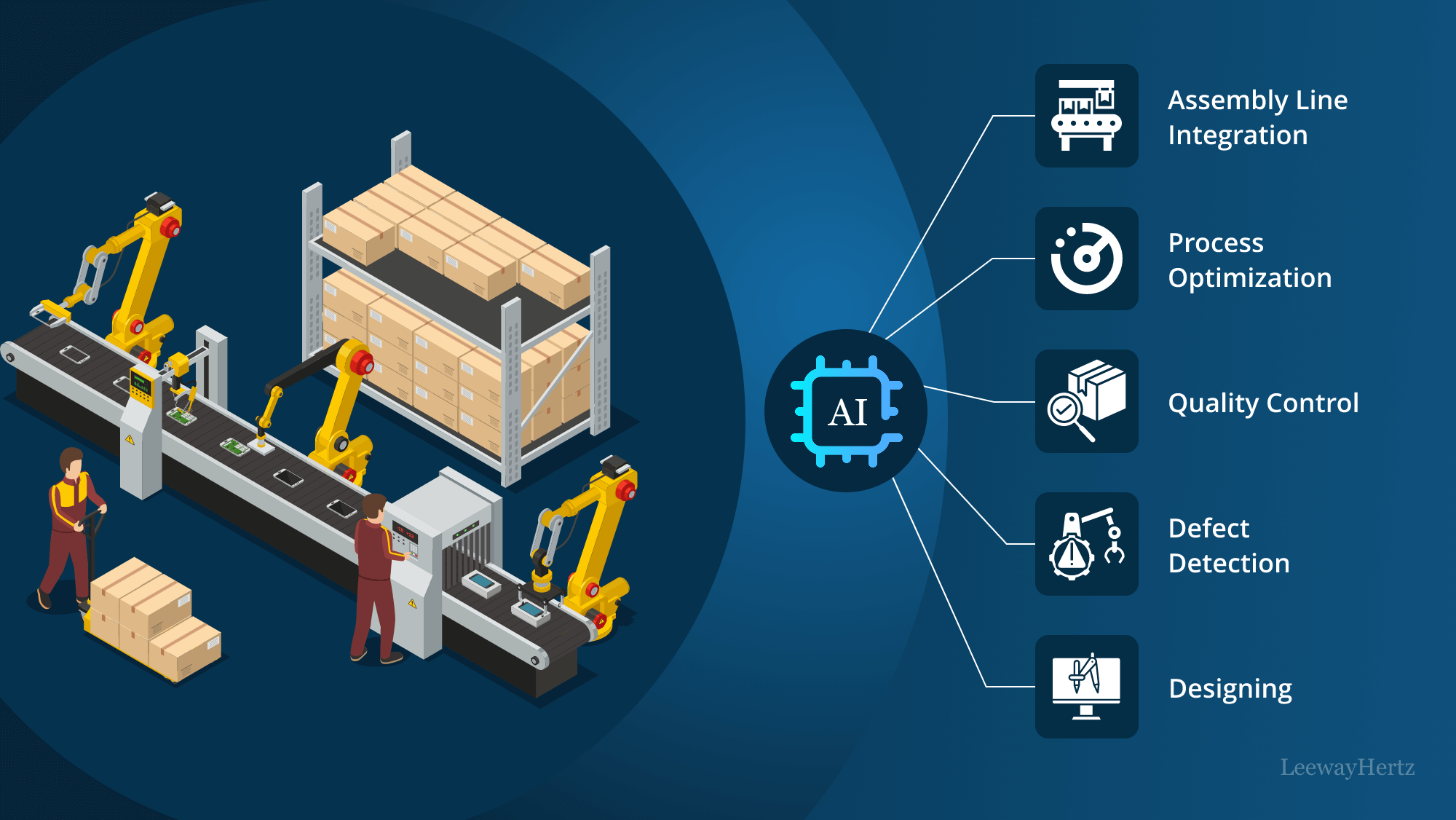

Artificial Intelligence (AI) in Forklift Design: Optimizing Operations

The integration of artificial intelligence (AI) in forklift design is revolutionizing the material handling industry, bringing unprecedented levels of efficiency and safety to operations. AI-powered forklifts are equipped with advanced algorithms that allow them to learn from their environments and improve their performance over time.

These forklifts can optimize routes, manage loads more effectively, and reduce energy consumption by adjusting their operations based on real-time data. By minimizing unnecessary movements and optimizing driving patterns, AI-powered forklifts enhance operational efficiency and contribute to significant cost savings.

In addition to improving efficiency, AI technologies play a pivotal role in enhancing safety. AI-powered forklifts can detect obstacles, assess their surroundings, and make instant decisions to avoid collisions, thereby reducing the risk of accidents and creating a safer working environment. This technology is particularly beneficial in busy warehouses where the risk of accidents is higher.

5G and IoT Impact: Real-Time Data and Enhanced Connectivity

The advent of 5G and IoT (Internet of Things) technologies is significantly impacting forklift operations by providing enhanced connectivity and real-time data analytics. The integration of 5G enables forklifts to communicate with each other and with central management systems more effectively, allowing forimproved fleet management. This seamless connectivity ensures that data from each forklift is transmitted instantaneously, providing managers with up-to-date information on forklift performance, location, and maintenance needs.

Ergonomic Design for Operator Comfort and Productivity

The ergonomic design of forklifts plays a critical role in enhancing operator comfort and productivity. Modern forklifts are increasingly being designed with ergonomics in mind, featuring adjustable seats, user-friendly controls, and better visibility.

These design elements are essential in reducing operator fatigue, which is a common issue in material handling operations. When operators are comfortable and less fatigued, they are less likely to make mistakes, leading to a safer working environment and higher operator performance.

Hydrogen Fuel Cells: The Future of Forklift Power

Hydrogen fuel cells are emerging as a promising alternative to traditional lead-acid and lithium-ion batteries for forklifts, offering a sustainable and efficient solution for powering material handling equipment. Unlike conventional batteries, hydrogen fuel cells produce zero emissions, making them an environmentally friendly choice that can significantly reduce the carbon footprint of forklift operations.

This clean energy technology is particularly beneficial for businesses looking to enhance their sustainability credentials while maintaining high levels of productivity.

Operator Training and Guidance: Ensuring Safe Forklift Operations

Effective operator training is crucial for maintaining a safe and productive workplace in forklift operations. Proper training equips operators with the necessary skills and knowledge to handle forklifts safely, thereby reducing the risk of accidents and workplace injuries. In regions like Houston and Humble, TX, where material handling is a critical component of many businesses, investing in comprehensive forklift training programs is essential to ensure that all operators are competent and confident in their roles.

Fleet Management and Maintenance

Effective fleet management and maintenance are crucial for reducing operational costs and enhancing the efficiency of forklift operations. Remote monitoring and predictive maintenance technologies play a pivotal role in achieving these goals.

By utilizing remote monitoring systems, businesses can gather real-time data on forklift performance, usage patterns, and maintenance needs. This data-driven approach allows for more precise scheduling of maintenance activities, minimizing unexpected breakdowns and reducing costly downtime.

Embracing Modern Technologies for a Safer and Efficient Future

Emerging technologies in forklift design and repair are transforming the material handling industry, making operations safer, more efficient, and more sustainable. From electric forklifts and AI-powered systems to hydrogen fuel cells and predictive maintenance, these innovations offer substantial benefits for businesses looking to enhance productivity and reduce costs.

For local businesses in Houston and Humble, TX, partnering with Upright Forklift Repair provides access to advanced solutions and expert services that can help you stay ahead in this evolving landscape. Contact us today to learn how we can support your forklift operations with the latest technology and professional expertise.