Welcome to Upright Forklift Repair, your premier destination for comprehensive forklift repair services, maintenance, and quality spare parts in Houston and Humble, Texas. Specializing in a wide range of forklift care, our expertise notably shines in the meticulous art of hydraulic cylinder seal replacements—a critical service for maintaining the efficiency and safety of your forklift operations.

With years of experience under our belts, our skilled technicians are dedicated to delivering unparalleled service quality, ensuring your forklifts are in optimal condition. Whether you’re facing operational challenges or simply seeking routine maintenance, Upright Forklift Repair stands ready to exceed your expectations with professionalism and precision.

Understanding Hydraulic Cylinders and Their Importance

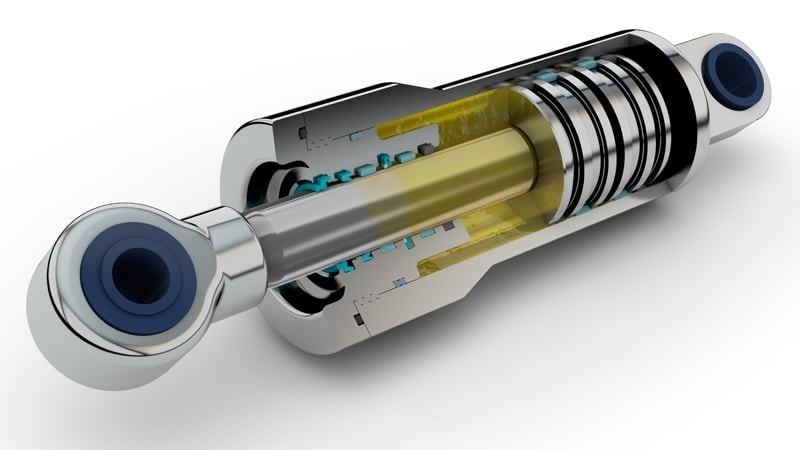

Hydraulic cylinders play a pivotal role in forklift operations, acting as the backbone for lifting and moving heavy loads with ease. At the heart of these cylinders are the cylinder rod and piston rod, components crucial for converting hydraulic energy into mechanical force. This process allows for the smooth and efficient operation of the forklift’s lifting mechanism.

Without properly functioning hydraulic cylinders, a forklift’s ability to lift and transport materials safely and effectively would be severely compromised. The integrity of these components is essential not just for the performance of the machine but also for the safety of the operator and the longevity of the forklift itself.

Identifying Common Issues: Leaking Hydraulic Cylinders

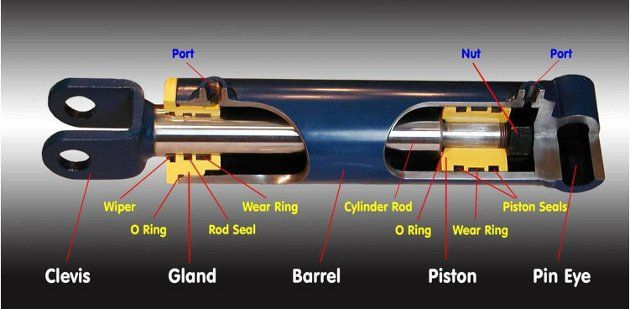

Leaking hydraulic cylinders can significantly impact the performance and safety of a forklift. The most common causes of leaks are worn piston seals and damage to the cylinder rod. Over time and through regular use, piston seals may deteriorate, losing their ability to maintain a tight seal and allowing hydraulic fluid to escape.

Similarly, any damage to the cylinder rod, such as scratches or dents, can compromise the seal’s integrity, leading to leaks. These issues not only reduce the efficiency of the forklift’s hydraulic system but can also lead to more significant problems if not addressed promptly, emphasizing the importance of regular inspections and maintenance to ensure the longevity and reliability of your equipment.

The Importance of Regular Hydraulic System Maintenance

Regular maintenance of your forklift’s hydraulic system is not just a recommendation; it’s a necessity to prevent costly damage and ensure operational efficiency. This includes thorough inspections of hydraulic lines and seal kits, crucial steps for identifying early signs of wear and potential issues.

Such preventive measures can save businesses from expensive repairs or replacements down the line. By ensuring that all components are in top condition, and any hydraulic fluid leaks are promptly addressed, operators can maintain optimal performance and extend the life of their forklifts, safeguarding their investment and ensuring continuous, safe operation.

Step-by-Step Guide: How to Replace Seals in a Hydraulic Cylinder

Replacing seals in a hydraulic cylinder is a meticulous process that demands attention to detail and the right tools. Here’s a step-by-step guide to help you through:

- Safety First: Ensure the forklift is turned off and safely supported. Wear appropriate safety gear.

- Relieve Pressure: Before starting, make sure all hydraulic pressure is released from the system to avoid accidents.

- Disassembly: Carefully remove the cylinder from the forklift. Use punch pliers to carefully dismantle the cylinder, paying close attention to the arrangement of components for reassembly.

- Remove Old Seals: Once the cylinder is open, inspect for damage and wear. Carefully remove the old seals from the piston and rod, noting their placement and orientation.

- Clean and Inspect: Thoroughly clean all parts of the cylinder, checking for any signs of damage or wear on the cylinder walls, piston, or rod. Replace any damaged components.

- Install New Seals: Carefully install the new seals, ensuring they are correctly oriented and seated. Use grease lightly to facilitate installation.

- Reassemble Cylinder: With new seals installed, reassemble the cylinder in the reverse order of disassembly. Ensure everything is tightly secured.

- Test: Once reassembled and reinstalled, test the hydraulic system for leaks and proper operation, making adjustments as necessary.

Tools and Components Needed for Seal Replacement

Replacing the seals in a hydraulic cylinder requires not just skill and patience but also the right tools and components. Essential items include:

- Seal Kits: Specific to your cylinder’s make and model, containing all necessary seals and o-rings.

- Punch Pliers and Seal Puller: For removing the cylinder and old seals without causing damage.

- Grease: To lubricate the new seals and facilitate installation.

- Clean Cloths and Cleaning Solution: For cleaning the cylinder and components during the process.

- Inspection Tools: Such as calipers or micrometers, to measure and inspect parts for wear or damage.

Choosing the correct type of seal is crucial, as using the wrong seal can lead to premature failure and leaks. Always refer to the manufacturer’s specifications when selecting replacement seals to ensure compatibility and reliability.

Preventing Future Leaks: Tips and Best Practices

To prevent future leaks in hydraulic systems, regular maintenance is key. Ensure routine checks for debris and dirt in the hydraulic oil, as contamination is a common cause of seal wear and failure. Also, the use of high-quality hydraulic fluid cannot be overstated; it not only preserves the integrity of the seals but also enhances the overall performance of the hydraulic system.

These practices, combined with timely seal replacements and system inspections, are vital in minimizing downtime and extending the lifespan of your forklift’s hydraulic components.

Upright Forklift Repair’s Expert Services

At Upright Forklift Repair, we pride ourselves on offering a comprehensive suite of services tailored to your forklift’s needs. Our expertise spans hydraulic cylinder repair, including precise seal replacements, ensuring your equipment operates at its best.

With a focus on quality and reliability, our professional service extends to thorough inspections, maintenance, and the provision of high-quality spare parts. Trust our skilled technicians to address your forklift’s hydraulic issues with efficiency and unmatched attention to detail, keeping your operations smooth and uninterrupted.

Why Choose Upright Forklift Repair for Your Forklift’s Hydraulic Repairs?

Selecting Upright Forklift Repair for your forklift’s hydraulic repairs means choosing peace of mind. Our experienced technicians are not only adept at diagnosing and fixing complex issues but are also committed to providing fast turnaround times, minimizing your equipment’s downtime.

By choosing us, you benefit from our dedication to using only the highest quality spare parts and our comprehensive understanding of hydraulic systems, ensuring your forklift is in the most capable hands. Let Upright Forklift Repair be your partner in maintaining your forklift’s performance and reliability.

Call to Action

Understanding the critical role of hydraulic cylinder seal replacements is just the beginning. For professional and reliable service that keeps your forklift running smoothly in Houston and Humble, turn to Upright Forklift Repair. Contact us today and ensure your equipment benefits from the highest standards of care and expertise.