In today’s busy industrial world, having a skilled forklift operator is very important for your business’s efficiency, specifically for improving the overall efficiency of your business operations. Forklifts, or lift trucks, are key tools. They are vital for many jobs, like those in warehouses, construction sites, and factories. This guide will help both new and experienced forklift operators learn important skills and knowledge. It will focus on how to drive forklifts safely and efficiently.

For local businesses in Houston and Humble, investing in the right forklift can lead to long-term gains in efficiency, safety, and cost-effectiveness. Companies such as Upright Forklift Repair specialize in forklift repair, service, and spare parts, offering expert support for businesses looking to maintain and optimize their fleets. Whether you’re looking to improve your current fleet or invest in new equipment, understanding the role of forklifts is key to making informed decisions for your business’s success.

Understanding Forklift Basics

Before you drive a forklift, it is important to understand the basics. Forklifts are heavy-duty trucks that help lift and move heavy loads easily. There are different types of forklifts, including each type of forklift designed for specific tasks, having its own unique traits and abilities.

It is key to know how different forklifts work, like electric ones and internal combustion forklifts (IC forklifts). Electric forklifts use batteries and are better for indoors because they do not produce emissions. In contrast, internal combustion forklifts use gasoline, diesel, or propane, giving them more power. These types can be used both indoors and outdoors.

Different Types of Forklifts and Their Uses

Electric Forklifts: These forklifts are great for indoor places like warehouses and factories, ensuring good indoor air quality. They have no emissions and run quietly. They come with cushion tires and work well on smooth surfaces, making them good for tight spaces and narrow aisles.

Internal Combustion Forklifts: These forklifts use gasoline, diesel, or propane. They offer more power and can do many tasks, but it’s essential to consider the cons as well. Models with pneumatic tires are best for outdoor use. They can handle rough surfaces and uneven ground easily.

Specialty Forklifts: Specialty forklifts are more than just standard ones. They include reach trucks and order pickers for specific needs. Reach trucks have extending forks for tall warehouses and can handle loads up to 6,000 lb. Order pickers are good at picking and moving single items efficiently.

Key Components of a Forklift

- Overhead Guard: The overhead guard protects the forklift operator. It stops falling objects from hitting them. It’s important to keep this guard in great shape and clear during use.

- Mast: The mast is the tall part that lifts and lowers items. It has strong rails that fit together for better support. Knowing how much weight the mast can handle is key for safe use.

- Carriage: The carriage is attached to the mast. It holds the forks and moves up and down the mast rails. This helps lift and lower loads accurately. The carriage also has a way to change the fork position.

Preparing to Drive a Forklift

Before using a forklift, safety should come first. You need to take the right steps to be safe. Start by checking the forklift carefully before you use it. Get to know how the controls work, and wear the right safety gear.

It’s also very important to know and follow your workplace’s safety rules. Always use the forklift carefully and responsibly. Remember, there are risks if you don’t handle heavy machinery properly.

Essential Safety Gear for Operating a Forklift

The Occupational Safety and Health Administration (OSHA) requires forklift operators to wear personal protective equipment (PPE) to keep safe from dangers.

Key safety gear includes:

- Hard Hat: A hard hat keeps the head safe from injuries if something falls. This is very important in places where things are above you.

- Safety Glasses: Safety glasses help protect the eyes from dust, debris, and chemical splashes. They are needed for using forklifts both indoors and outdoors.

- Steel-Toe Boots: Steel-toe boots protect the feet from heavy things that could fall. They are important for safety in factories and warehouses.

For those who work with propane forklifts, extra care is needed. Propane is a flammable gas. Always make sure the propane tank is secured properly and handled carefully to avoid leaks or accidents.

Pre-Operation Checklist: Ensuring Forklift Readiness

A thorough pre-operation checklist is crucial before operating a forklift to ensure it is in safe working order and to prevent potential accidents or breakdowns.

This checklist should include:

| Area | Check |

| Fluids | Engine oil, coolant, fuel |

| Tires | Condition, pressure |

| Brakes | Pedal functionality |

| Steering | Smoothness, responsiveness |

| Lights | Headlights, taillights |

| Horn | Functionality |

| Forks | Straightness, damage |

| Overhead Guard | Condition, visibility |

By diligently following this pre-operation checklist, operators contribute to a safer work environment and a longer lifespan for their forklifts, reducing downtime and maintenance costs. Remember, a few minutes spent on inspection can prevent costly repairs and potential accidents later.

Beginner’s Guide to Operating a Forklift

Once you know the basics of forklifts and safety rules, it’s time to practice what you’ve learned. Operating a forklift needs both good knowledge and real experience. This beginner’s guide will show you the key steps to operate a forklift.

We will explain how to start the engine, how to use the controls, and how to move and carry loads safely. Please practice these steps in a safe place while an experienced operator is watching you.

What You Will Need to Get Started?

Before you start using a forklift, it’s important to have the right equipment and credentials:

- Certification: Make sure you have the required certification to operate a forklift. OSHA requires all forklift operators to receive proper training and certification before they can operate a forklift.

- Forklift Training: Sign up for a complete forklift training program. This program should teach you both the theory and hands-on skills needed to operate a forklift safely.

After you complete your training and get certified, you need to collect the right equipment for safe operation:

- Hard Hat

- Safety Glasses

- Steel-Toe Boots

- High-Visibility Vest (recommended)

Step 1: Starting the Forklift

The way to start a forklift can be a bit different based on the forklift type.

Internal Combustion Forklifts: Put the key in the ignition and turn it to start the engine, just like starting a car. Wait for the engine to warm up before you engage the transmission.

Electric Models: Electric forklifts work in another way. First, turn on the battery disconnect switch found at the back of the forklift. Make sure it is in the “On” position. Next, turn the key to the “Run” position. You should see a battery discharge indicator on the dashboard showing how much battery is left.

Always check the manufacturer’s operating manual for detailed steps that match the forklift you are using. Not following these steps can lead to accidents, equipment damage, and injuries.

Step 2: Basic Maneuvering and Handling Techniques

Maneuvering a forklift is very important for safety. First, get to know the forklift’s controls. These include the steering wheel, accelerator, brake pedal, and hydraulic levers. Practice driving in an open space to understand how the forklift responds.

When you drive, always look in the direction of travel. Use the horn to let others know you are there. It’s also important to keep good ergonomics to avoid tiredness and injuries. Make sure your seat and controls are adjusted for a comfortable and safe position.

Remember, smooth and steady movements are essential for safe forklift operation. Avoid quick or jerky movements, sharp turns, and sudden stops. These can make the forklift less stable and may cause accidents.

Step 3: Lifting and Transporting Loads Safely

Lifting and moving loads are key parts of using a forklift. Before lifting any load, check how much it weighs, its size, and where its center of gravity is. Make the forks the right width and make sure they are even to support the load well.

Tilt the mast slightly back to make it more stable while you transport. When you get close to the load, line up the forks with the openings on the pallet or where you need to lift. Raise the load slowly to the height of the pallet you want, but keep it as low as you can for better stability.

It’s very important to drive slowly and carefully when moving heavy loads. Watch out for bumpy surfaces, slopes, or objects that could make it unstable. When you lower the load, do it slowly and carefully.

Step 4: Parking and Shutting Down the Forklift

Parking a forklift safely is very important for a safe work area. When you choose a place to park, make sure it is on flat ground and far from obstacles, doorways, or fire exits. Always engage the parking brake and lower the forks to the ground. Ensure the forks are not blocking any walkways.

To turn off the forklift, follow the guidelines from the manufacturer. If your forklift has an internal combustion engine, turn the key to the “Off” position. If it is an electric model, turn the key switch to “Off” and then switch off the battery disconnect.

Don’t forget to check for overhead clearance before you park or use the forklift. This is especially important in small spaces or near any overhead structures. If you don’t check, you might cause accidents and damage.

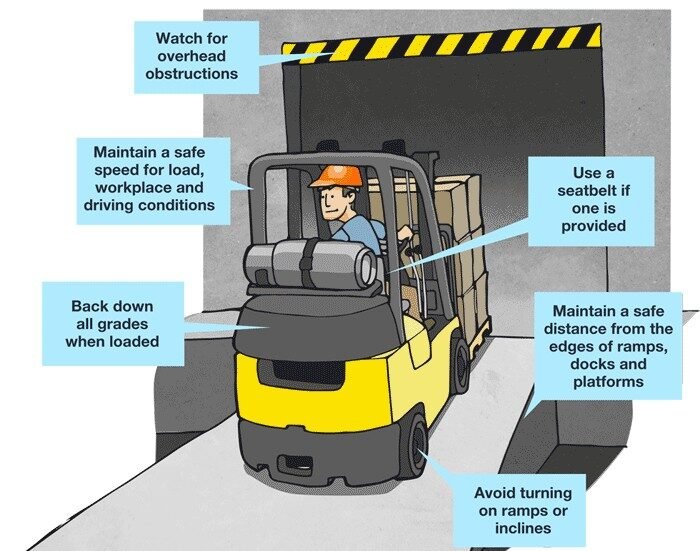

Advanced Forklift Driving Tips

Mastering advanced forklift driving skills can help you work better and stay safe. These skills include moving in tight spaces, handling difficult ground, and managing loads more effectively.

When you get better at using a forklift, it leads to a smoother work process and fewer accidents. By using these advanced skills, you can become more important to your job, boost productivity, and cut down on delays.

Navigating Tight Spaces and Challenging Terrain

Maneuvering in tight spaces requires precision and control. Use a three-point turn technique to make the most of the forklift’s small turning radius, which may be as small as 72.1 inches, while navigating narrow aisles. Always check your mirrors and stay aware of your surroundings to prevent accidents.

When driving outside, pay attention to the terrain. For bumpy ground, choose forklifts with pneumatic tires. They provide better grip and stability. Adjust your speed and be careful on slopes or hills.

Remember, practice is key. Look for chances to enhance your maneuvering skills in safe areas first. As you gain confidence, slowly add more difficult tasks.

Load Management Best Practices

Effective load management is very important for safety and efficiency. Make sure loads are secure and balanced on the forks. This helps to prevent tipping or spills. Always use pallets when you can. They provide a stable base for the load.

Overloading a forklift can cause safety issues and can also decrease the lifetime of your equipment. Always check the forklift’s load capacity chart. Never go over its limits.

When you focus on load management, you help create a safer work environment. This also helps to reduce wear and tear on the forklift. In the long run, this can lower the total cost of ownership by cutting maintenance costs and avoiding downtime.

Conclusion

To sum up, becoming a good forklift operator takes knowledge, practice, and focus on safety, which includes proper forklift operator training. It is important to know the basics, prepare carefully, and follow the rules for operating a forklift. Whether you are just starting out or trying to improve your skills, safety should always come first. You should also follow the best practices.

By using advanced driving tips, like handling tough areas and managing loads well, you can boost your forklift driving skills. Remember, regular practice and being alert will help you operate a forklift safely and effectively. Stay informed, stay safe, and work on improving your forklift driving abilities.

Don’t let forklift issues slow down your business. Contact Upright Forklift Repair today for expert services in Houston and Humble, and ensure your fleet remains efficient and safe.

Frequently Asked Questions

Is a Special License Required to Operate a Forklift in Texas?

In Texas, you don’t need a special license to drive a forklift. However, OSHA requires that all forklift drivers get certified through training provided by their employer. This certification shows that operators have the right skills and knowledge to use forklifts safely.

How Long Does It Take to Become Proficient in Driving a Forklift?

The time it takes to get good at operating a forklift can change. It depends on how skilled the forklift operator is and how detailed the forklift training program is. In general, you will need about 40 hours of both classroom learning and practical experience to feel comfortable using a forklift.

What Are the Most Common Mistakes Beginners Make When Learning to Drive a Forklift?

Common mistakes are bad load handling, driving too fast, forgetting to use the horn, and having poor ergonomics. These mistakes can lead to forklift accidents. Fixing these problems with good training and practice can make things safer.