Knowing how to start a forklift is crucial for operators to ensure safety and efficiency in their daily operations. This seemingly simple task is foundational for the effective and safe use of a forklift, affecting not just the machine’s performance but also the safety of the operator and those in the immediate environment.

Upright Forklift Repair, with its vast expertise in forklift repair, service, and providing spare parts, stands out as a leading provider in Houston and Humble. Our understanding of the nuances of forklift operation, combined with our commitment to excellence, ensures that your forklift is always in prime condition, ready to perform its essential tasks.

Understanding the Basics of Forklift Operation: How to Start a Forklift

The Essential Role of the Ignition System

The ignition or fuel system serves as the heart of your forklift’s engine, sparking into life the processes that power the machine. A well-maintained ignition system is crucial for a smooth start and optimal operation. Ignition problems can lead to starting difficulties, affecting the forklift’s reliability and efficiency. Regular checks and maintenance by professionals like Upright Forklift Repair can prevent these issues, ensuring your forklift is always ready when you need it.

Fuel System Insights: Ensuring Your Forklift Is Ready to Go

The fuel system is another critical component that needs regular inspection and maintenance. Ensuring that your forklift has enough fuel and that the fuel system is free from blockages or leaks is essential for a trouble-free start and operation. A well-maintained fuel system supports the efficient use of the forklift, ensuring that it operates at peak performance with minimal downtime.

Pre-Start Checklist: Ensuring Safety and Readiness

A thorough pre-start inspection is essential for ensuring both the safety of the forklift operator and the operational readiness of the forklift itself. This crucial step cannot be overlooked, as it identifies potential issues that could lead to accidents or mechanical failures.

Key elements of this checklist include ensuring the parking brake is securely engaged, verifying the forklift battery is fully charged and properly connected, and checking the emergency brake lever to confirm it’s functioning correctly.

Additionally, inspecting the forklift for any visible signs of wear or damage, confirming that all safety devices are in place and operational, and checking fluid levels are all part of this vital routine. This inspection helps prevent accidents and mechanical issues, making it a fundamental practice for safe and efficient forklift operation.

Common Reasons Your Forklift Won’t Start

When faced with a forklift that won’t start, several common issues might be the culprit. A dead battery is often to blame, potentially caused by extended periods of inactivity or failure to maintain the battery properly. Bad connections within the forklift’s electrical system can also prevent the engine from starting, requiring a thorough check of all cables and connections for corrosion or looseness..

Fuel System Checks for a Non-Starting Forklift

When troubleshooting a forklift that won’t start, it’s crucial to ensure that the fuel system is not the issue. Begin by checking that there is enough fuel in the tank; it may seem obvious, but it’s a common oversight. Next, inspect the fuel system for any signs of blockages or leaks that could prevent fuel from reaching the engine.

Ensure that the fuel lines are intact and the fuel filter is clean and free from obstruction. These checks help guarantee that the fuel system is delivering fuel efficiently to the engine, ruling it out as a cause of starting problems.

Operational Tips for Starting Your Forklift

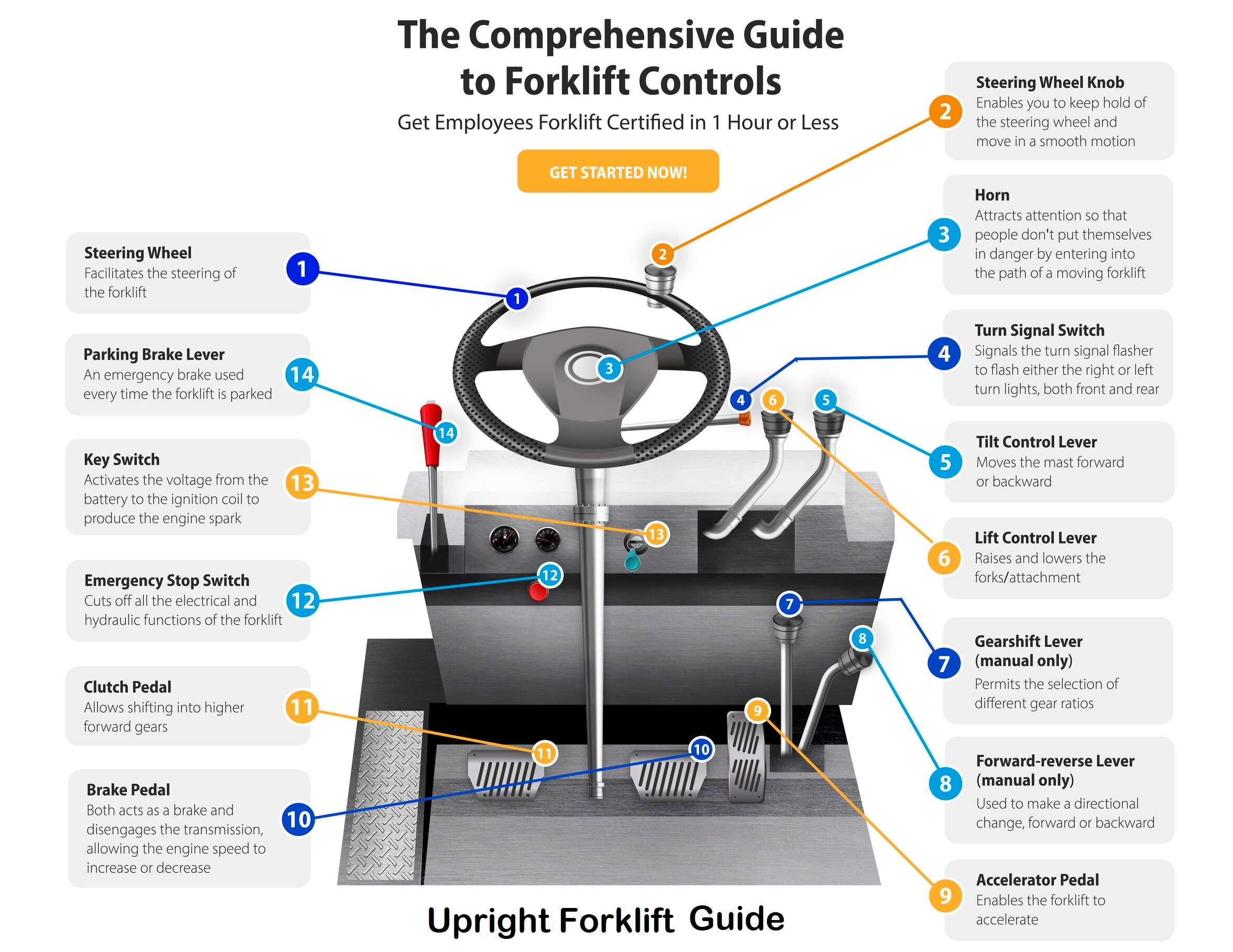

Starting a forklift properly is key to ensuring its longevity and operational efficiency. To begin, ensure you are seated correctly and that all controls, including the forward and reverse pedal and control levers, are in their neutral positions. Engage the parking brake to prevent unintended movement. Turn the ignition key to start the forklift, but avoid cranking the engine for too long, as this can damage the starter motor.

Once the forklift is running, allow the engine to warm up before operating the machine, ensuring smoother performance. Following these steps can help ensure that your forklift starts correctly and is ready for safe operation.

Adjustments and Settings for Smooth Operation

Before using your forklift, making the necessary adjustments and settings is crucial for smooth operation. Adjust the seat and mirrors to ensure comfort and visibility. Check that the mast is in the forward position and that the forks are tilted forward slightly, which aids in safe and efficient load handling.

Ensure that all controls, including the mast and tilt levers, are within easy reach and operate smoothly. These adjustments not only contribute to the operator’s comfort but also enhance the forklift’s functionality, making operations more efficient and reducing the risk of accidents.

What to Do if Your Forklift Operates Differently?

If your forklift begins to operate differently, such as moving slowly or if you’re losing control more easily, it’s essential to address these changes promptly. Start by checking the hydraulic fluid and engine levels, as insufficient fluids can affect performance. Inspect the tires for wear and ensure they are properly inflated, as this can impact movement and control.

Additionally, review the forklift’s recent maintenance history to identify any overlooked issues. If the problem persists, consult a professional. Recognizing and responding to unusual behaviors quickly can prevent further damage and maintain operational safety.

Maintenance Tips to Prevent Starting Issues

Regular maintenance is crucial in preventing starting issues and ensuring the longevity of your forklift. Establishing a consistent maintenance schedule that includes checking the forklift engine, steering wheel, and other critical components can significantly reduce the risk of problems.

Regularly inspect the battery, clean the terminals, and check the electrolyte levels to prevent power issues. Change the oil and replace the air and fuel filters as recommended by the manufacturer to ensure the engine runs smoothly.

Adhering to a comprehensive maintenance schedule can help identify and resolve potential issues before they lead to starting problems.

Your Partner in Forklift Service and Spare Parts

Upright Forklift Repair stands as your premier partner in forklift truck repair, servicing, and providingspare parts in Houston, TX, and Humble. Our dedicated team of experts specializes in diagnosing and fixing any issues, ensuring your forklift operates at peak efficiency.

From regular maintenance to emergency repairs and a comprehensive inventory of spare parts, we provide all the services necessary to keep your forklift running smoothly. Trust Upright Forklift Repair for all your forklift needs, where our commitment to quality service and customer satisfaction is unmatched.

Optimizing Forklift Performance: Beyond the Basics

The Role of the Operator’s Manual and Certification

Operating a forklift manual safely and efficiently goes beyond basic knowledge of starting and maneuvering the machine. An operator’s manual is not just a guide but a comprehensive resource that covers everything from the forklift’s engine specifics to its emergency power system. Achieving operator’s certification is a testament to one’s proficiency, ensuring that the operator understands the intricacies of the forklift, from the tilt forward of the mast to the delicate balance required when the load stays balanced on the forks.

Mastering Control and Operation

Forklift operation is an art that requires understanding the machine’s behavior in various conditions. Whether it’s navigating through tight spaces with the mast in a vertical position or adjusting the load’s width to ensure stability, the operator must be adept at controlling the forklift.

This includes using the inching pedal for precise movements, shifting gears smoothly to prevent losing control, and knowing how to manually change the forklift’s direction with the shifter lever.

The emergency brake lever and the parking brake are critical for safety, ensuring the forklift remains stationary when required. Operators must be familiar with the forklift’s ignition system, including the proper way to engage spark plugs and use the control levers for starting the engine and controlling the machine’s movements.

Navigating Challenges: Slow Speed and Load Management

Occasionally, a forklift may operate at a slow speed or exhibit signs of losing control, indicating issues that need immediate attention. This could be due to a variety of factors, including a dead battery or a bad connection in the electrical system.

Understanding how to troubleshoot these issues, from checking the forklift battery to ensuring there is enough fuel in the fuel system, is essential for maintaining operational efficiency.

Load management is another critical aspect of safe forklift operation. Ensuring that the fork underneath the load is completely inserted and that the load stays balanced during transport is crucial. The operator must know how to adjust the fork closer or farther away, depending on the load’s width and weight, to maintain stability. This requires a deep understanding of the forklift’s capacity and the ability to adjust the mast and forks accordingly.

Preventative Maintenance: The Key to Longevity

Regular maintenance is the cornerstone of forklift operation. A comprehensive maintenance schedule that includes checking the forklift engine, steering wheel, and brake pedal, along with ensuring the emergency power system is functional, can significantly extend the life of the forklift. This includes routine checks of the spark plugs, ensuring the control levers operate smoothly, and keeping the machine’s manual handy for troubleshooting.

Operators should also be trained to perform visual inspections before each use, checking for any signs of wear or damage that could affect the forklift’s performance. This includes examining the steering column, ensuring the tines are positioned correctly, and verifying that the safety harnesses are fully engaged.

Ensuring Forklift Efficiency and Safety

Upright Forklift Repair is committed to providing comprehensive service and support for all your forklift needs. From routine maintenance to emergency repairs and providing spare parts, our goal is to ensure your forklift operates safely and efficiently.

Understanding the nuances of forklift operation, from starting the engine to managing loads and performing regular maintenance, is crucial for maximizing productivity and extending the lifespan of your equipment. Trust Upright Forklift Repair to be your partner in maintaining optimal forklift performance.

Call to Action

Don’t let starting troubles slow down your operations. Contact Upright Forklift Repair today for expert forklift repair, service, and spare parts in Houston and Humble. Let us help you keep your forklifts running smoothly and efficiently, so you can focus on what you do best.