In the bustling industrial and commercial landscapes of Houston and Humble, forklifts are indispensable tools that drive efficiency and productivity. However, the high-intensity nature of their usage often leads to wear and tear, with leaking hydraulic hoses being a common yet significant issue. A leaking hose can not only halt your operations, costing you valuable time and resources, but it can also pose serious safety risks to your operators and the environment.

Recognizing the urgency of these situations, Upright Forklift Repair emerges as your trusted local solution. Specializing in repairing, servicing, and providing spare parts for forklifts, our expertise ensures your equipment remains operational and safe.

Emphasizing the importance of professional repair services, Upright Forklift Repair stands ready to address your forklift leaking hose repairs in Houston and Humble, minimizing downtime and maximizing your operational efficiency.

Understanding Forklift Leaking Hose Issues

Signs of a Damaged Hydraulic Hose

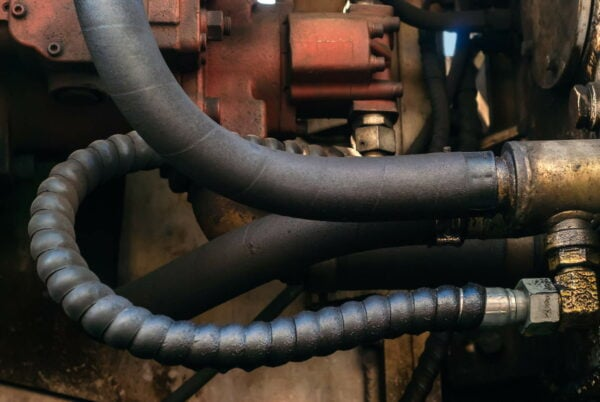

Recognizing the early signs of a damaged hydraulic hose is crucial for maintaining operational efficiency and ensuring workplace safety. Key indicators include visible abrasion or cracks on the hose surface, noticeable leaks or drips of hydraulic fluid, and a marked decrease in system efficiency.

These signs suggest that the integrity of the hose is compromised, potentially leading to sudden failure or dangerous leaks. By staying vigilant for these symptoms, businesses can preemptively address hose issues before they escalate into costly repairs or operational hazards.

Causes of Hydraulic Hose Leaks

Hydraulic hose leaks are often attributed to several factors, with abrasion, cracks, and wear and tear being the most prevalent. Abrasion occurs when the hose rubs against other parts of the forklift or external objects, gradually wearing down its surface.

Cracks can develop from excessive pressure, poor handling, or exposure to extreme temperatures, compromising the hose’s structure. Wear and tear, a natural outcome of regular use, can weaken the hose over time. Understanding these causes is essential for preventive maintenance and ensuring the longevity of your forklift’s hydraulic system.

The Risks of DIY Hose Repair Solutions

Why Duct Tape Isn’t Your Friend

In the world of quick fixes, duct tape has become a go-to for many, promising a fast and easy solution to almost any problem. However, when it comes to hydraulic hose repair, duct tape is not only a temporary fix but a dangerous one. Attempting to patch up a leaking hydraulic hose with duct tape can lead to increased pressure and the risk of burst lines, posing serious safety hazards to operators and equipment.

This makeshift solution fails to address the root cause of the leak and can lead to more significant, costly repairs down the line. Trusting in duct tape for hydraulic hose repair is a gamble with your safety and operational efficiency that just isn’t worth taking.

The Importance of Professional Hydraulic Hose Repair

The complexity and high-pressure nature of hydraulic systems demand a level of safety, precision, and knowledge that only professional repair services can provide. Opting for professional hydraulic hose repair ensures that all aspects of the repair process, from diagnosis to replacement, are handled with the utmost expertise. Another consideration is using an abrasion resistant hose, such as Caterpillar Tough Guard hose that is designed for severe abrasion applications.

Professionals bring an understanding of the intricate balance required within hydraulic systems, ensuring repairs are not only effective but also durable. Safety is paramount, and professional services guarantee that the right techniques and materials are used to restore your equipment’s functionality without compromising it.

Comprehensive Solutions for Forklift Hydraulic Hose Repair

Emergency Hydraulic Hose Repair Services

Unexpected breakdowns don’t have to bring your operations to a standstill. Upright Forklift Repair offers emergency hydraulic hose repair services designed to respond quickly and efficiently to your needs. With a focus on minimizing downtime, our team is equipped to provide on-site assessments and repairs, ensuring that your forklift is back in operation as swiftly as possible. Our service is rooted in a commitment to quick response times and effective solutions, addressing your emergency repair needs with the urgency they deserve.

Replacing Hydraulic Hoses: What You Need to Know

When it comes to replacing hydraulic hoses, understanding the importance of quality and compatibility is key. High-pressure systems require hoses that can withstand intense conditions without faltering. Upright Forklift Repair specializes in hydraulic hose replacement, offering a wide selection of hoses that meet the diverse needs of forklift models and applications.

Our experts ensure that every replacement hose is perfectly matched to your forklift’s specifications, providing a seamless and reliable solution. With our comprehensive approach, replacing hydraulic hoses becomes a straightforward process, ensuring your equipment operates safely and efficiently.

Why Choose Upright Forklift Repair for Your Hose Needs?

Expertise in Forklift Leaking Hose Repair

Upright Forklift Repair stands out in the Houston and Humble areas for its unparalleled expertise in forklift leaking hose repair. Our team is equipped with the knowledge and experience necessary to address even the most complex hydraulic hose issues.

We understand the critical role forklifts play in your operations, and we are dedicated to providing fast, effective solutions that minimize downtime. With a deep understanding of hydraulic systems and a commitment to excellence, Upright Forklift Repair is your go-to expert for all your forklift hose repair needs.

Wide Range of Services and Spare Parts

Beyond our repair expertise, Upright Forklift Repair offers a comprehensive range of services and an extensive inventory of spare parts, including hydraulic fittings and replacement hoses. Our commitment to maintaining a full stock of essential parts ensures that we can quickly respond to your needs, providing timely replacements and repairs without unnecessary delays.

Whether you’re in need of routine maintenance or emergency repair services, our team is prepared to support your forklift operations with quality parts and expert service.

The Process of Repairing a Forklift Hydraulic Hose

The process of repairing a forklift hydraulic hose involves several critical steps to ensure safety and efficiency. Initially, our professionals conduct a thorough inspection to diagnose the source of the leak or damage. This step is crucial for understanding the extent of the issue and planning the appropriate course of action.

Following diagnosis, the repair process may involve the use of a hydraulic hose repair kit, which contains all the necessary tools and materials to fix the hose effectively. Contrary to temporary solutions like tape, our professionals employ durable repair methods that restore the hose’s integrity and functionality, ensuring your forklift operates safely and reliably.

Preventative Maintenance: Keeping Your Forklift in Top Shape

Preventative maintenance is key to ensuring your forklift operates efficiently and safely over its lifespan. Regular checks should be conducted to monitor the condition of hydraulic hoses, fluid levels, and overall equipment integrity. Ensuring that the hydraulic fluid is at the proper level and free from contamination can prevent many common issues. By adhering to a scheduled maintenance plan, you can identify potential problems before they escalate, maintaining optimal operating conditions and prolonging the life of your forklift.

Call to Action

Hydraulic hose issues are crucial for maintaining the safety and efficiency of your forklift operations. Ignoring these problems can lead to costly downtime, potential safety hazards, and extensive repairs. Upright Forklift Repair, serving Houston and Humble, specializes in the quick and effective resolution of such issues, emphasizing customer satisfaction and safety.

Recognized as the Best Forklift Service and Repair in Houston, our team is committed to delivering reliable service, equipped with the expertise and parts necessary to keep your forklift running smoothly. For professional assistance and peace of mind, contact Upright Forklift Repair today. Trust us to ensure your forklift is in top condition, so you can focus on your business without interruption.