In the bustling industrial sectors of Houston and Humble, ensuring the safety of personnel working around heavy machinery is paramount. At Upright Forklift Repair, we specialize in forklift repair, service, and spare parts, and we understand the critical importance of integrating advanced safety technologies to enhance workplace safety.

One such vital technology is the proximity warning system. Proximity warning systems play a crucial role in safeguarding workers and preventing accidents in various industrial settings, offering an additional layer of protection that keeps your workforce safe.

What is a Proximity Warning System?

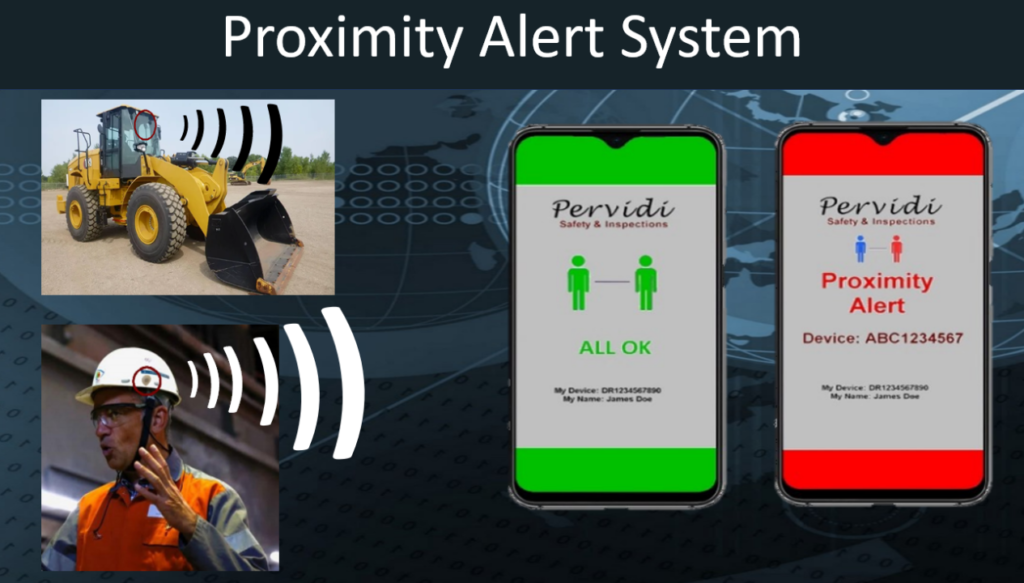

A proximity warning system is an advanced safety mechanism designed to alert operators and pedestrians when they are in close proximity to moving vehicles or heavy equipment. These systems create a detection zone around machinery, using sensors to monitor for any intrusions. When an object or person enters this exclusion zone, an alert is generated to warn both the operator and nearby personnel.

These alerts can be visual, audible, or both, helping to mitigate potential hazards and prevent accidents. Related systems, like the ground proximity warning system used in aircraft, also function on similar principles, ensuring safety by alerting operators to immediate danger.

How Proximity Warning Systems Work?

Proximity warning systems function by using sensors to monitor the area around heavy machinery. When an object or person enters the detection zone, the system triggers an alert to warn the operator and nearby personnel. This immediate warning allows for quick action to prevent collisions and other incidents.

The types of alerts generated can vary, including visual signals such as flashing lights and audible alarms. These systems are especially useful in areas with heavy equipment and blind spots, where the risk of accidents is higher due to limited visibility and potential hazards.

Key Benefits of Proximity Warning Systems

Enhanced Pedestrian Safety

Proximity warning systems significantly reduce the risk of accidents involving pedestrians in industrial settings. By creating exclusion zones around moving vehicles, workers are alerted in real time to potential hazards, ensuring their safety.

Reduction in Collisions

With real-time alerts, the likelihood of collisions between vehicles and obstacles is greatly minimized. This is especially vital in environments with heavy equipment and blind spots.

Improved Operational Efficiency

By preventing accidents, these systems contribute to smoother operations and less downtime due to incident investigations and repairs. This improved efficiency can lead to increased productivity and reduced operational costs.

Protection of Assets

Heavy machinery and vehicles represent significant investments. Proximity warning systems help protect these assets from damage caused by accidents. This not only saves money on repairs but also extends the lifespan of the equipment.

Compliance with Safety Regulations

Installing proximity warning systems demonstrates a commitment to workplace safety, helping businesses comply with safety regulations and reducing liability. Compliance with regulations is not only a legal requirement but also a moral responsibility, ensuring that the workforce is protected and accidents are minimized.

By incorporating proximity warning systems into your safety protocols, you can create a safer and more efficient workplace. At Upright Forklift Repair, we are committed to helping businesses in Houston and Humble enhance their safety measures through the implementation of these advanced systems.

Applications in Various Industrial Sectors

Proximity warning systems are versatile and can be applied across multiple industries, including:

- Construction: Enhancing safety on construction sites with heavy machinery and numerous personnel

- Warehousing: Preventing accidents in busy warehouses with high traffic of forklifts and pedestrians.

- Manufacturing: Protecting workers in manufacturing plants with complex machinery and equipment.

Common Features of Proximity Warning Systems

Proximity warning systems come equipped with several common features:

- Sensors: These detect the presence of objects or people within the detection zone.

- Alerts: Visual and audible alarms to warn operators and personnel of immediate danger.

- Range: Coverage capabilities vary, ensuring that the system meets specific site requirements.

Addressing Blind Spots and Immediate Danger

One of the significant advantages of proximity warning systems is their ability to address blind spots and areas of immediate danger. By creating restricted areas around heavy machinery, these systems ensure that operators are always aware of potential hazards, even in hard-to-see zones. This mitigation of risks in blind spots is crucial for maintaining a safe working environment.

Importance of Real-Time Alerts

Real-time alerts are crucial in preventing accidents. By providing immediate warnings, proximity warning systems enable operators to take quick action, avoiding potential collisions and ensuring the safety of everyone on site. These real-time alerts are vital in maintaining a safe and efficient workplace. For example, a forklift operator alerted to a pedestrian entering a detection zone can stop the vehicle instantly, preventing a potential incident.

Installation and Maintenance

Installing proximity warning systems involves integrating sensors and alert mechanisms into your existing machinery. At Upright Forklift Repair, we ensure that the installation process is seamless and that the systems are correctly calibrated for optimal performance. Regular maintenance is also essential to ensure that the systems function correctly and continue to provide accurate alerts.

Integration with Existing Safety Protocols

Proximity warning systems complement other safety measures in place at your facility. By integrating these systems with your existing safety protocols, you can create a comprehensive safety plan that addresses all potential hazards and ensures the well-being of your workforce.

Installation and Maintenance

Installing proximity warning systems involves integrating sensors and alert mechanisms into your existing machinery. At Upright Forklift Repair, we ensure that the installation process is seamless and that the systems are correctly calibrated for optimal performance.

Regular maintenance is also essential to ensure that the systems function correctly and continue to provide accurate alerts. Proper maintenance includes checking sensors, updating software, and ensuring that all components are working as intended.

Integration with Existing Safety Protocols

Proximity warning systems complement other safety measures in place at your facility. By integrating these systems with your existing safety protocols, you can create a comprehensive safety plan that addresses all potential hazards and ensures the well-being of your workforce. These systems work alongside traditional safety practices such as training programs, safety signage, and protective gear, creating a multi-layered approach to maximizing workplace safety.