Introduction

For businesses in Houston, TX, forklifts are not just equipment; they are the backbone of day-to-day operations, especially in industries like warehousing, manufacturing, and construction.

The efficiency and safety of these heavy-duty machines hinge significantly on the quality of their parts and are a testament to the benefits the lift truck platforms provide.

Whether it’s for routine maintenance or critical repairs, the right forklift parts can mean the difference between smooth operations and costly downtime.

However, finding trustworthy vendors and high-quality forklift parts in Houston’s bustling market hyster forklift parts can be a daunting task.

With a plethora of options, it’s challenging to discern which suppliers offer parts that genuinely meet your needs in terms of quality, durability, and compatibility with your specific forklift models.

In this blog, we’ll guide you through the key aspects of finding the best forklift parts in Houston.

We’ll discuss how to identify quality parts, evaluate the expertise of vendors, and find reliable suppliers.

Additionally, we’ll provide tips on comparing different options and making informed purchasing decisions when manufacturing forklifts.

Plus, we’ll introduce Upright Forklift Repair as a reliable option for those times when the repair job just gets a bit too complicated.

Let’s dive into the world of forklift parts and ensure your forklifts are always in top condition!

Understanding Forklift Parts Houston TX: What You Need to Know

When it comes to maintaining and repairing forklifts or material handling equipment, understanding the different yale forklift parts and their functions is crucial.

In this section, we’ll explore the common forklift parts, how to identify high-quality components, and why using quality parts is essential for optimal forklift performance and safety.

Types of Lift Truck Parts: New and Remanufactured Forklift Parts

- Tires: Forklift tires can be pneumatic (air-filled), solid, or polyurethane, each suited for different working environments. Pneumatic tires are ideal for rough outdoor terrain, while solid and polyurethane tires are better for indoor or smooth surface operations for your lift trucks.

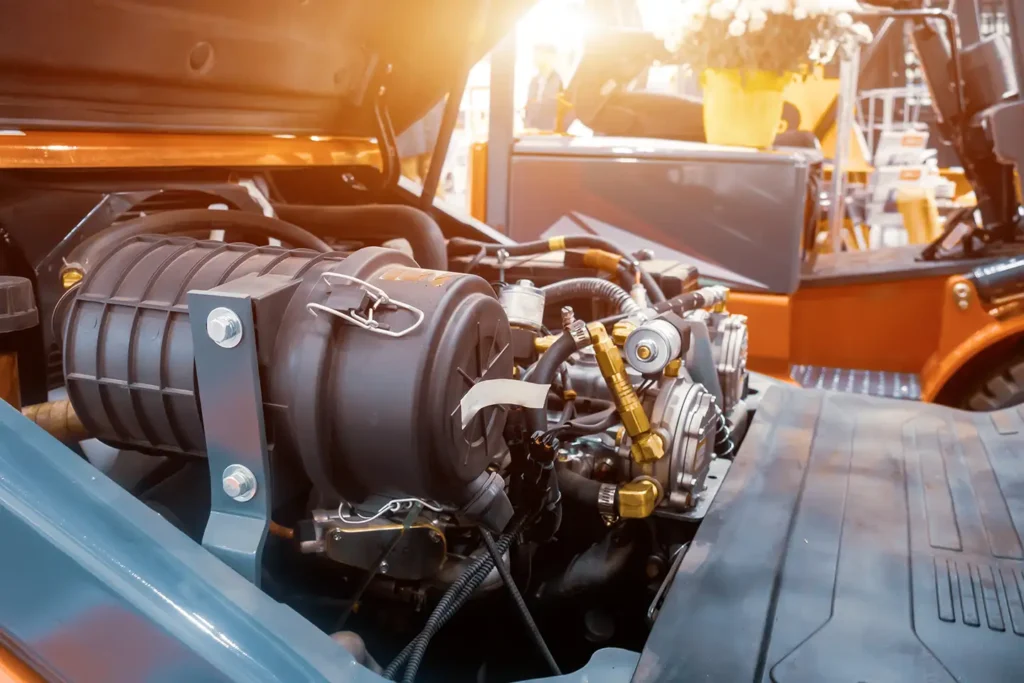

- Engines: The engine is the powerhouse of the forklift. Depending on the forklift, engines can be internal combustion (diesel, gasoline, or propane) or electric lift trucks.

- Hydraulic Systems: These systems are crucial for lifting and moving loads. They include cylinders, pumps, valves, and fluid lines, all working together to control the forklift’s lifting and lowering functions for lift trucks.

- Masts and Forks: The mast is the vertical part that lifts and lowers loads, and the forks are the horizontal parts that hold the load. They come in various sizes and types, depending on the load capacity and application for your lift trucks.

- Brakes and Steering: Reliable braking systems and responsive forklift steer axles are vital for maneuvering the forklift safely, especially when transporting heavy loads.

Other Parts Could Include

- forklift alternators

- forklift throttle body

- engine powered trucks

- skid steer loaders

- komatsu forklift parts

- forklift extension boom

- forklift drive axle

- hyundai forklift parts

- overhead lifting jack

- manitou forklift parts

- industrial trucks

- forklift differential

- fork mounted sweeper

- fuel injected engines

- fuel system break

- internal combustion engine

- lift mast

- rotating brake drum

- wheel loaders

- forklift starters

- tow hitch

- snow bucket attachments

- gantry crane

- hydraulic drive motors

- forklift rotator

- movable steerable wheel

- automatic control systems

- diesel engines

- lift masts

- fork mounted work platform

- lifting machinery

- gradall forklift parts

- tine carriage lifting capacity

Quality Indicators

Identifying high-quality of forklift trucks and parts is key to ensuring longevity and reliability of forklift forks and material handling equipment. Here are some indicators of quality:

- Material Quality: High-grade steel and robust materials indicate durability and strength, especially in parts like forks and masts.

- Brand Reputation: Established brands often have a track record of quality. Researching brand history and customer reviews can provide insights into their reliability.

- Certifications: Look for parts that meet industry standards and have necessary certifications, indicating they have passed rigorous testing.

- Compatibility: Ensure the parts are specifically designed for your forklift model to avoid compatibility issues.

Importance of Quality Parts

Using quality parts has a direct impact on both the performance and safety of your forklift:

- Enhanced Performance: Quality parts ensure smoother operation, higher efficiency, and reduced wear and tear.

- Safety: Forklifts are inherently dangerous machines. High-quality parts reduce the risk of accidents caused by part failures.

- Longevity: Quality parts last longer, reducing the frequency of replacements and repairs, thereby saving costs in the long run.

- Compliance: Using certified, high-quality parts helps in adhering to safety regulations and standards, avoiding legal and financial repercussions.

By understanding the types of forklift parts, quality indicators, and their importance, you can make informed decisions that ensure the safety and efficiency of your forklift operations.

Finding the Right Vendor in Houston

Selecting the right vendor for forklift parts in Houston is a critical step in ensuring you get quality products and reliable service.

In this section, we’ll discuss the advantages of choosing local vendors for forklift seats, how to effectively research potential suppliers, and ways to assess their expertise.

Local Vendor Advantages

- Easier Communication: Local vendors offer the benefit of direct, face-to-face communication. This can lead to better understanding and quicker resolution of any issues.

- Faster Delivery: Being in the same city, local vendors can often provide faster delivery times, which is crucial when you need a part urgently to minimize downtime.

- Local Knowledge and Support: Local vendors are more likely to understand the specific needs and challenges of Houston-based businesses. They can offer tailored advice and support that’s relevant to your local operations.

- Building Relationships: Working with local suppliers allows you to build long-term relationships, which can be beneficial for future negotiations, custom solutions, and reliable service.

Researching Vendors

- Online Reviews: Check online platforms for customer reviews and ratings. These can provide real insights into the vendor’s reliability and quality of service.

- Industry Recommendations: Consult with industry peers or forums. Recommendations from other businesses in the same industry can be incredibly valuable.

- Check Business Listings: Look up the vendor in local business directories or the Better Business Bureau to verify their legitimacy and review any complaints or accolades.

- Social Media and Websites: A vendor’s social media presence and website can offer insights into their business practices, customer engagement, and updates on their products and services.

Expertise Evaluation

- Years in Business: Longevity can be a sign of a vendor’s experience and stability in the market. A company that has been in business for many years likely has a track record of satisfying customers.

- Certifications and Accreditation: Check if the vendor has relevant industry certifications or accreditations. This can indicate their commitment to quality and adherence to industry standards.

- Client Testimonials and Case Studies: Look for testimonials or case studies on their website. These can provide examples of their expertise in action and feedback from actual customers.

- Technical Knowledge and Support: Engage with the vendor to gauge their technical knowledge and the level of support they offer. A vendor who can provide detailed, knowledgeable answers to your queries is likely to be a reliable source for quality parts.

Finding the right vendor in Houston for your forklift parts requires careful research and consideration. By focusing on local advantages, thorough research, and evaluating the expertise of the vendor, you can establish a partnership that benefits your business in the long run.

Trustworthy Vendors: A Key to Success

Choosing a trustworthy forklift electrical parts vendor is crucial when sourcing forklift parts. Reliable vendors not only provide quality parts but also contribute significantly to the efficiency and longevity of your forklift operations. Here’s what to look for in a trustworthy forklift engine vendor and some red flags to avoid:

Signs of a Trustworthy Vendor

- Transparency: Trustworthy vendors operate with a high level of transparency. They provide clear information about their products, including pricing, origin, and specifications.

- Quality Customer Service: Look for vendors who are responsive, attentive, and willing to go the extra mile to meet your needs. Good customer service is often a reflection of the overall quality of the business.

- Warranty Offers: A vendor confident in their products will offer warranties. This shows they stand behind their parts and are committed to customer satisfaction.

- Proven Track Record: A history of satisfied customers and successful transactions is a strong indicator of a reliable vendor. Ask for references or look for online testimonials.

Red Flags to Avoid

- Hidden Fees: Be wary of vendors who are not upfront about their pricing. Unexpected charges can indicate a lack of transparency.

- Poor Communication: If a vendor is consistently slow to respond or evasive in their answers, it could signal potential problems with reliability.

- Lack of Professionalism: Unprofessional behavior, such as missed appointments or incomplete information, can be a sign of a vendor’s overall unreliability.

Upright Forklift Repair: Your Reliable Technician in Houston

Upright Forklift Repair in Houston stands out as a reliable technician, especially for complex forklift controller repair jobs. We have consistently demonstrated a commitment to quality and customer satisfaction. Our team is knowledgeable and responsive, ensuring that any forklift repair needs are addressed promptly and efficiently. Upright Forklift Repair offers transparent pricing, comprehensive services, and our expertise in handling intricate repair jobs. If you ever find that a forklift fuel tank repair job is becoming too complicated, reach out to us at Upright Forklift Repair for expert assistance.

Choosing the right vendor is a crucial step in maintaining the performance and safety of your forklifts. By being aware of the signs of a trustworthy vendor and the red flags of unreliable ones, you can make informed decisions that will benefit your operations in the long run. And for those challenging repair jobs, remember that Upright Forklift Repair is a reliable option in Houston.

Comparing Forklift Parts: Making the Right Choice

Selecting the right forklift parts is more than just a matter of finding the cheapest option. It’s a careful balance of price, quality, compatibility, and the support you receive.

Here’s how you can make an informed decision when comparing forklift parts new or remanufactured forklift parts:

Price vs. Quality

- Understand the True Cost: The cheapest option isn’t always the most cost-effective in the long run. Low-quality parts may wear out faster, leading to more frequent replacements and higher overall costs.

- Invest in Quality: Higher-priced parts often come with better quality, longevity, and reliability. Consider this an investment in your forklift’s performance and lifespan.

- Budget Wisely: Set a realistic budget that considers both the initial cost and the potential long-term savings from using higher quality parts.

Compatibility with Your Forklift

- Model Specifics: Always ensure that the parts you’re considering are compatible with your lift truck make and model. Using incompatible parts can lead to malfunctions and safety hazards.

- Consult with Experts: If you’re unsure about compatibility, consult with experts or the manufacturer. They can provide valuable guidance on which parts work best with your specific forklift model.

Warranty and Support

- Warranty Coverage: A good warranty can provide peace of mind and protection against defects or premature failure. Look for parts that come with a substantial warranty period.

- Assess Support Services: Consider the level of customer support provided. Reliable vendors offer excellent after-sales support, including assistance with installation, maintenance tips, and handling warranty claims.

- Read the Fine Print: Understand the terms and conditions of the warranty. Know what’s covered and what’s not, and how to claim warranty services if needed.

When comparing forklift parts, it’s important to look beyond just the price tag.

Consider the quality, compatibility with your forklift, and the warranty and support services offered.

These factors will help you make a choice that ensures safety, efficiency, and value for money in your forklift operations.

By taking a balanced approach, you can ensure that your used forklift fuel system remains a reliable and productive asset to your business and the fork carriage lifting capability.

Making the Purchase: Tips and Best Practices

Finalizing the purchase of forklift parts is a crucial step that requires careful consideration and strategy.

From negotiating better deals to ensuring the quality of crown forklift parts, there are several best practices to follow. Here’s how you can navigate the purchase process clark forklift parts effectively:

Negotiation Strategies for Material Handling Equipment

- Do Your Homework: Research the average market prices and have a clear understanding of the part’s value before entering negotiations.

- Communicate Your Needs: Clearly convey your requirements and expectations. This understanding can help in finding a middle ground that benefits both parties.

- Volume Discounts: If you’re buying in bulk or foresee a long-term need, ask for a volume discount. Vendors are often willing to lower prices for larger or repeated orders.

- Flexibility and Alternatives: Be open to alternative solutions or products the vendor might suggest. Sometimes, a slightly different part could offer better value or performance.

- Build a Rapport: Establishing a good relationship with the vendor can lead to more favorable terms. Show them the potential of a long-term partnership.

Verifying Parts Before Purchase

- Inspect the Parts: If possible, physically inspect the parts for any defects or inconsistencies. Check for proper labeling and packaging.

- Ask for Certifications and Documentation: Ensure that the parts come with the necessary certifications and documentation to verify their authenticity and quality.

- Confirm Compatibility: Double-check that the parts are compatible with your specific forklift model. Cross-reference part numbers and specifications if needed.

- Trial Period or Return Policy: Ask if the vendor offers a trial period or a return policy. This can provide an additional layer of assurance.

Building Long-Term Relationships with Vendors

- Reliable Supply Chain: A good relationship with a vendor ensures a more reliable supply chain and quicker access to necessary parts.

- Better Support and Service: Long-term partners are more likely to provide you with superior customer service, technical support, and faster response times.

- Customized Solutions: As a trusted customer, you might receive more customized solutions tailored to your specific needs.

- Feedback and Improvement: A long-term relationship allows for open feedback, which can lead to improvements in the products and services you receive.

Making the purchase of forklift parts requires thoughtful negotiation, thorough verification of parts, and an emphasis on building lasting relationships with vendors.

By adopting these strategies, you can ensure a more efficient, cost-effective, and reliable procurement process for your various forklift accessories and parts needs.

Remember, a successful forklift attachments purchase is about more than just the immediate transaction; it’s about establishing a foundation for ongoing support and mutual growth.

Conclusion

In this comprehensive guide, we’ve explored the vital aspects of finding and purchasing the right forklift parts in Houston, TX. To recap:

- Understanding Forklift Parts: We emphasized the importance of knowing the different types of forklift parts, identifying high-quality components, and recognizing the impact of these parts on forklift performance and safety.

- Finding the Right Vendor: We discussed the advantages of choosing local vendors, offered tips on researching potential suppliers, and highlighted how to evaluate a vendor’s expertise.

- Trustworthy Vendors: We outlined what to look for in a reliable vendor, warned against common red flags, and recommended Upright Forklift Repair as a trusted technician for more complex repair jobs.

- Comparing Forklift Parts: We advised on balancing price and quality, ensuring compatibility with your forklift, and the importance of warranty and support in your decision-making process.

- Making the Purchase: We provided strategies for negotiating better prices and terms, steps for verifying parts before purchase, and the benefits of building long-term relationships with vendors.

Investing time in finding the right forklift parts and vendors is crucial for the longevity and efficiency of your forklift operations. Quality parts ensure safety and performance of clamp forklift attachments, while a good vendor relationship can offer reliability and peace of mind.

For those times when repairs become too complicated, remember that Upright Forklift Repair in Houston is a reliable and skilled forklift lift truck service provider. Their expertise and commitment to quality service make them an excellent choice for complex forklift repair needs.

By following the guidelines and tips in this blog, you can make informed choices that will enhance the performance and lifespan of the hydraulic fluid power your forklifts, ultimately contributing to the smooth running of lift trucks and your business operations.